SCREW-IN SOLDERLESS™ PLUGS

SCREW-IN SOLDERLESS™ PLUGS

DESCRIPTION

The first and only Patented Solderless Patch cable system to legitimize the product category for both sound quality and reliability.

Evidence Audio introduces the perfect 1/4″ Phone plug for use with its award-winning Monorail signal cable.

The perfect combination of Monorail sound quality, the convenience to build and rebuild without solder, a compact cable and plug combination, and no signal failures in the middle of a song!

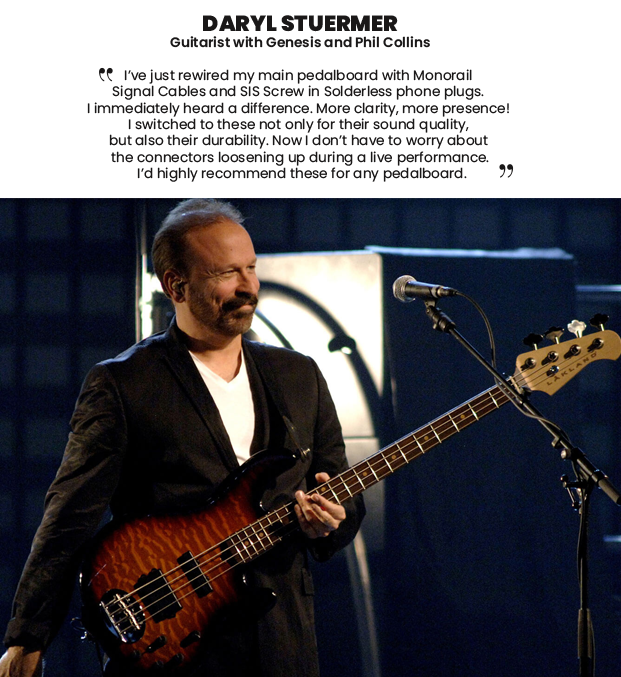

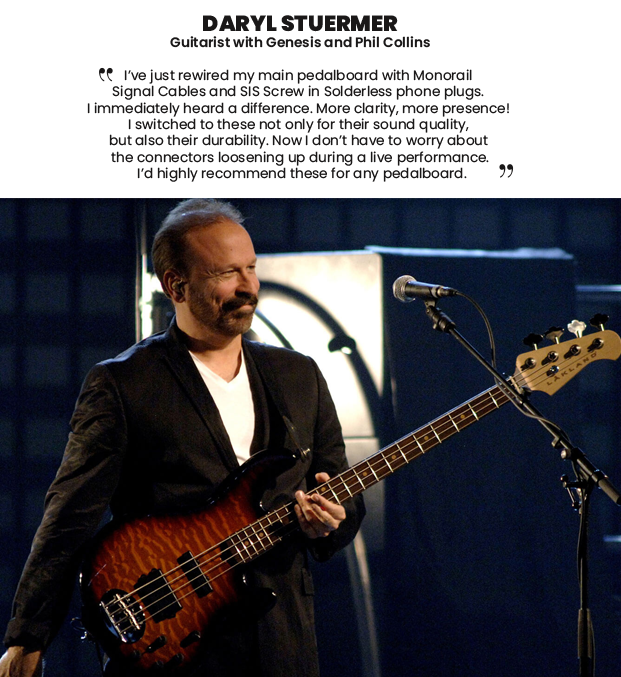

As used by David Gilmour, Noel Gallagher, Graham Coxton, Ed O’Brien of Radiohead, Josh Smith, Guthrie Govan, Andy Timmons, Guy Pratt, Steven Rothery, and many others.

DESIGN

Our Proprietary high-purity IGL copper conductors for distortion-free midrange and high frequencies.

The solid-core center conductor eliminates the negative effects of strand interaction on the audio signal.

20 awg conductor size keeps skin-effect distortions outside the audio spectrum while offering ample cross-sectional area.

Parallel-run shield provides 98% coverage with minimal crosstalk.

Coaxial geometry with low capacitance.

Carbon-loaded extrusion for protection from triboelectric noise.

CONNECTORS

The inside of the tip of the SIS™ plug is carefully machined to have “threads” of a precise size and pitch. These threads cut and re-shape the soft conductor of the Monorail cable when turned around it several times.

When you push the prepared cable into the SIS plug, the soft copper will find the hole. When you turn the plug 1 or 2 times the harder brass core of the plug will catch and cut into the copper conductor. When you feel this happen you put the cap in place and screw the SIS plug into the cap.

This action turns the soft copper deeper into the SIS core – Mashes the ground up against the SIS body to make ground contact (airtight as the copper is deformed inside pushing air from the connection). This seals the red jacket at the exit tightly so that the cable will not come loose from the plug and the cap will not come loose from the plug body. When finished the tip/core connection with the Monorail is also air-tight and in many ways better than a soldered connection. If you unscrew the SIS plug and remove the Monorail cable you can see the soft copper has been shaped to meet with the SIS core.

ASSEMBLY INSTRUCTIONS

1) REMOVE the thin black (conductive) skin from around the white insulation. If it touches where the conductor needs to enter, you’ll create a complete short or partial short with weak signal.

2) Do not cut up your cable into short pieces before attaching the plugs. Instead attach the first plug to your long/entire supply of cable. Measure the length required to the other plug. Cut and attach the second plug to complete your cable. Rinse, repeat.

3) Wear rubber gloves to get a good grip and spare sore fingers when closing tight.

ASSEMBLY FOR THE RIGHT-ANGLE CONNECTORS

ASSEMBLY FOR THE STRAIGHT CONNECTORS:

Push the cable into the plug and when you seat the core, rotate the plug about 10-12 full revolutions (straight plug only). This will simultaneously thread the copper core into the tip of the plug and screw the body of the plug onto the cable jacket. You only need the jacket to enter the plug a few millimeters.